Studios

-

Support

-

Contact us

-

Products

Studios

All of Guided Ultrasonic’s systems use the Guided Wave Testing (GWT) method to inspect metallic structures for the presence of defects caused by corrosion, erosion, or cracks.

GWT is a non-destructive method for determination of the condition of elongated structures – commonly pipes, but rails etc. can also be tested.

A ring of transducers is attached around the circumference of the pipe to generate acoustic waves that propagates along the pipe in both directions from the transducer ring, while ‘guided’ by the boundaries of the pipe wall. Changes in cross section of the pipe, e.g. caused by metal loss due to corrosion or erosion, generate an echo, reflection, of the waves. This feature (defect) can be located relative to the transducer from the speed of the wave and time of arrival of the echo. The transducer ring is operated in ‘pulse-echo’ mode, i.e. it is also detects the echoes.

The waves travel metres to tens of metres. Thus the full area of the pipe wall can be tested for defects. This is a key advantage of the method – unlike with ultrasonic testing, in which only the area under the transducer is tested, it is not necessary to know in advance where the risk of corrosion / erosion is greatest. You do not need to get lucky in locating the transducer.

You can read a detailed description of how Guided Wave Testing works here.

Guided Wave Testing was developed as a practical method of testing of engineering structures at Imperial College, London in the 1990s, and proven in a wide range of industrial applications in the decade that followed

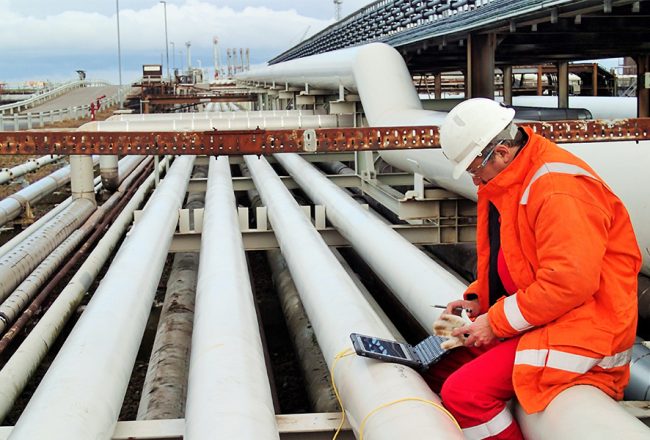

Many inspection companies worldwide use GWT equipment to perform an inspection. A removable transduction ring is wrapped round the circumference of the pipe at / near the section of pipe to be inspected, signals are generated and received back using a signal processing and data storage unit attached to the ring, then the ring is removed (and insulation restored as necessary). The deliverable is a report of the condition of the structure at that point in time. See details of the procedures and capabilities of Guided Ultrasonics’ GWT inspection systems here.

Guided Ultrasonics’ sister company, Guided Ultrasonics Training, operates gold standard training for GWT inspectors, certified by industry bodies – details here.

If the transduction ring is permanently installed on the pipe, test data can be generated on an ongoing basis, at intervals of hours to days, enabling the condition of the structure to be monitored over time

For a detailed description of our monitoring system technologies see here.

Guided Ultrasonics, and select partners, uses these systems to deliver monitoring services under long-term (3 / 5-year) service agreements – see here.

Guided Ultrasonics has one of the world’s largest and strongest teams in Non-Destructive Testing (NDT) technologies – sensor physics, ultrasonics data analysis, and machine learning. The board, management and development teams all have engineers with PhDs in NDT from Imperial College, the birthplace of modern GWT, ensuring that all aspects of the company’s activities are deeply informed by the capabilities of the technology.