Long Range Screening

This case study demonstrates the capability of the Wavemaker® System to screen long lengths of pipework from a single location. In this case, 230m of pipe was screened from a single location.

Studios

This case study demonstrates the capability of the Wavemaker® System to screen long lengths of pipework from a single location. In this case, 230m of pipe was screened from a single location.

This case study demonstrates the capabilities of the C-Scan, which is a synthetic focusing tool to determine the axial position and circumferential orientation of defects and pipe features.

Many sections of pipework within petrochemical plants are located high above the ground where they cross roadways or other pipe racks. Guided wave testing offers a unique solution to minimise access cost.

Earth walls are a common feature in petrochemical plants and tank farms where corrosion is often located at the soil/air interface. Guided Wave Testing can inspect both this interface and the buried section.

The Wavemaker® is an advanced NDT system capable of exciting guided waves to screen long lengths of pipework from a single location. In most straight pipe cases, tens of metres of pipes can be easily inspected with a 100% volumetric

Slug catchers are typically used in the oil and gas industries to collect slugs at the outlet of pipelines which transports gas & liquid together. In general, they are large in diameter (>48″) and highly susceptible to internal corrosion and

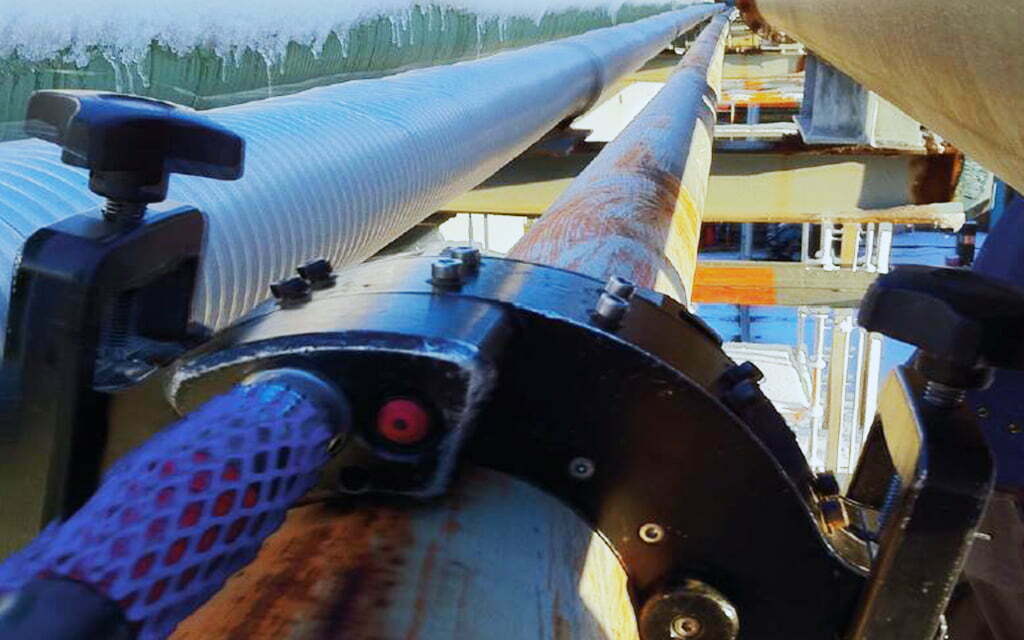

Corrosion under pipe supports (CUPS) is one of the leading causes of pipe failure. In most cases, supports have poor inspectability and maintainability because of the difficulty to access the area of interest.This case study describes a real inspection job

Corrosion under insulation (CUI) is a severe form of localized external corrosion which occurs in carbon and low alloy steel pipe that has been insulated. CUI is common in refineries and process plants that typically operate equipment at elevated temperatures

Bends or elbows are common pipe fittings which are susceptible to corrosion and erosion. Using the C-Scan, defects at elbows can be detected and prioritised.

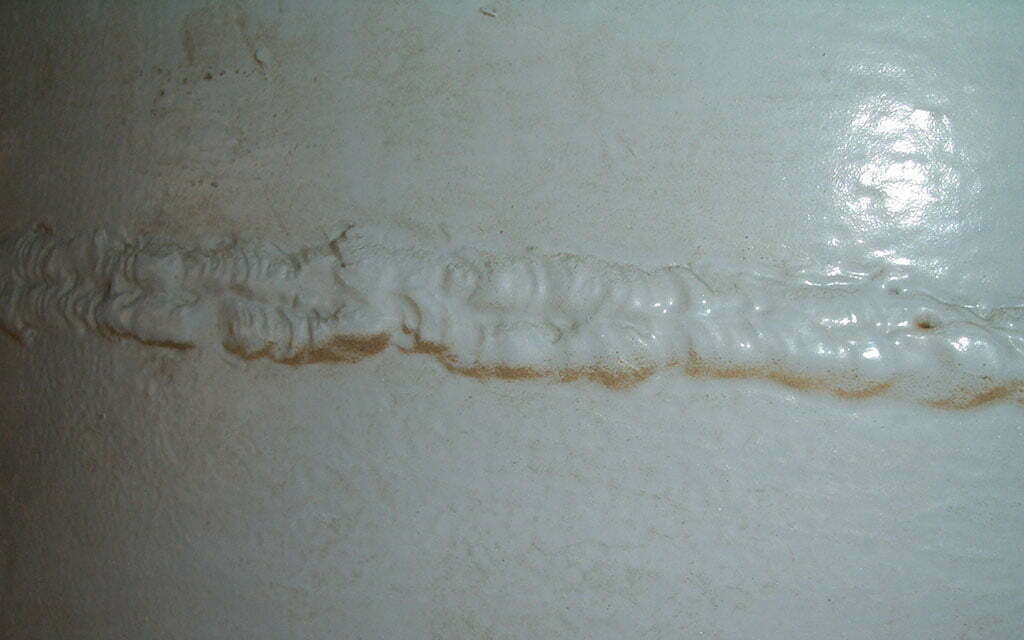

With the advanced interpretation tools such as frequency sweeping and C-Scan, defective welds are usually detected as part of the guided wave inspection.