Studios

-

Support

-

Contact us

-

Products

Studios

Monitoring systems deliver accurate and timely corrosion rates.

Correlating changes in corrosion rates with changes in operating parameters creates insights enabling more informed decisions about

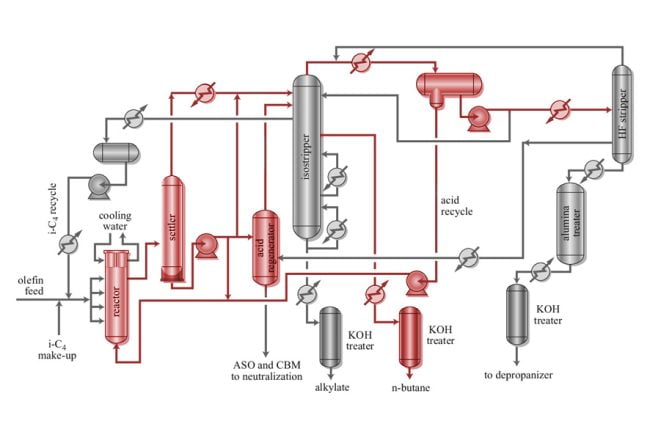

Contact between highly concentrated acid and carbon steel forms a stable iron fluoride layer.

Contact with an acid/water mix forms an unstable and non-protective hydrate scale – this swells and can detach.

Process upsets – temperature or water content variations, or changes in feedstock quality changes – drive aggressive, transient corrosion.

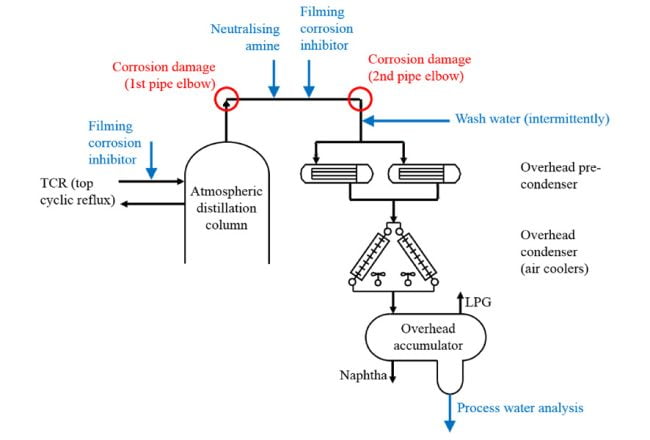

HCl, NH4Cl, amine hydrochloride salt corrosion

Visibility of corrosion rate, and correlating this with changes in process parameters informs mitigation

Example overhead configuration, with inhibitor injection and corrosion locations.

Flexibly meeting demanding requirements